T)he safety of consumers is a top priority for A.I.S.E. and its member companies involved in placing liquid detergent capsules on the European market. Liquid capsules were introduced into European markets in the early 2000s as an innovative, easy to use compact detergent format for laundry, machine dishwashing and floor cleaning.

A.I.S.E.’s stewardship of liquid detergent capsules

Ensuring the safe use of liquid detergent capsules

In 2012, A.I.S.E. launched its first voluntary product stewardship programme (PSP) for liquid laundry detergent capsules (LLDCs) with the aim to help significantly reduce incidents involving these products such as ingestion or eye exposure by young children.

Scope of the programme

The LDC PSP is open to all companies placing liquid detergent capsules on the market in Europe and involves additional commitments over an above compliance with EU legislation for the product category that includes (not exclusively) the EU Regulation on Classification Labelling and Packaging (CLP) and the Detergent Regulation.

Commitments

The first programme included packaging and labelling measures, as well as consumer education, for which a dedicated and preventive communication campaign has been developed called “Keep Caps from Kids”. Later revisions of the programme extended it to cover all liquid detergent capsules (LDCs), and additional safety measures. Improvements have been made to the visual panels placed on product packs and calling the consumer to adopt safe use and storage measures when using capsules. The commitments undertaken by companies implementing the industry PSP cover:

- Product specifications

- Child impeding measures such as reinforced packaging closures and reduced visibility of the capsules

- Use of visible industry-wide safety icons and labelling such as A.I.S.E.’s safe us icons and safe use yellow panel

- An advertising code of conduct and industry-wide safety messages in brand communication

- Communication of the industry’s campaign web portal www.keepcapsfromkids.eu

Today, most major manufacturers of the product liquid detergent capsules are signatories to the PSP, driving best practices in safe use communication for the product. This includes Henkel, Procter & Gamble, McBride, Persan, Reckitt, SmellWell and Unilever.

Collaboration with European Poison Centres

Since the introduction of the PSP, A.I.S.E. collaborates with European Poison Centres to better understand accident circumstances and root causes and publishes reports monitoring the evolution of incidents in Europe based on Poison Centre data.

In conjunction with several poison control centres across Europe, the occurrence of accidents is monitored on an ongoing basis and is regularly assessed and reported.

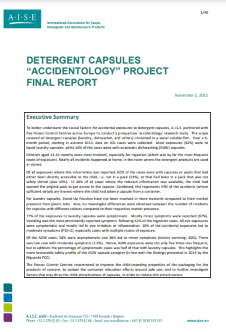

In 2014, A.I.S.E. carried out a large-scale prospective research study in collaboration with five Poison Centres, to help better understand accident circumstances and thus to confirm that the most appropriate measures are taken to address the safety concern. The observations of this research were confirmed in a similar study undertaken by the European Commission. The findings of this research led to subsequent reviews and updates of the PSP.

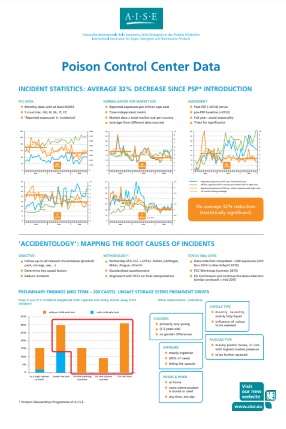

Since the introduction of the industry’s PSP, the number of incidents reported to the Poison Centres have decreased on average by 32%. The preliminary findings of the data indicate that unsafe storage seems to be the prominent cause of incident involving children. A.I.S.E. continues to prominently promote the need to keep capsules out of reach of children through its communication campaigns on-pack and online.

Monitoring progress and reporting on incidents

Since the first A.I.S.E. Product Stewardship Programme on liquid laundry detergent in 2012, A.I.S.E. has regularly reported on the evolution of incident numbers as the PSP measures are implemented by companies. These reports include quantitative incident tracking to better understand the root causes of liquid laundry detergent capsules ingestion incidents. The aim is to assess incident frequency both in absolute terms, as well as relative to potential developments in the liquid laundry detergent capsules market size.

A.I.S.E. partners with five Poison Centres (PCs) to carry out this qualitative accidentology research. The PCs are based in Dublin (Ireland), Göttingen (Germany), Milan (Italy), Prague (The Czech Republic) and Utrecht (The Netherlands). They serve a combined population of approximately 90 million inhabitants. The study scope covers all detergent capsules (laundry, dishwasher and others) contained in a water-soluble film. Over a six-month period details of incident circumstances of 401 cases were systematically collected.

Most accidental exposures (82%) involved liquid laundry capsules, while 16% of cases involved automatic dishwashing (ADW) capsules.

- The study shows that 66% of incidents involved capsules or packs that were directly accessible to a child i.e. capsules or packs not safely stored.

- In 44% of cases, the exposed child managed to take a capsule from a container.

The accidentology report released by A.I.S.E. and five European Poison Centres includes results, key learnings and recommendations from the Poison Centres.

Ensuring compliance with CLP Regulation

Liquid laundry detergent capsules must comply with EU Regulation on Classification Labelling and Packaging (CLP). In 2014, CLP was amended and the Soluble Packaging Regulation introduced (EU) 1297/2014. This introduced specific provisions into CLP for LLDCs classified as hazardous according to the Regulation. In doing so, this made many aspects of the industry’s product stewardship programme mandatory in EU legislation, while also introducing additional requirements for the capsules.